A motor breakdown is the last thing any facility wants to happen, but every machine will inevitably run into failure sooner or later, even with proper care and maintenance. When facing motor issues, you can get a replacement or an electric motor rewind in Singapore. Seeing as your choice will lead to thousands of dollars saved or lost, it only makes sense to thoroughly assess what each entails and which one is best suited for your unique needs. To help you arrive at an informed decision, the following contents outline what sets motor replacement and rewinding apart.

1. Objective

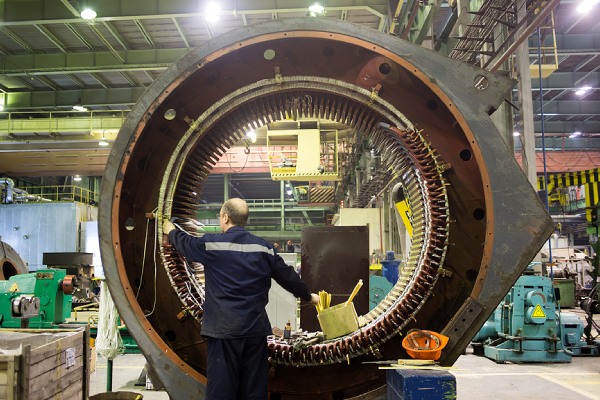

A motor rewind is a restorative process that involves replacing a motor’s worn windings with new ones, which are then insulated to prolong the overall motor’s service life and restore its efficiency. Not every motor will be a good candidate for rewinding as it requires a motor unit’s essential components to be intact or at least not beyond repair, which mainly includes the stator core and rotor laminations. Otherwise, it is unsalvageable.

In contrast, a motor replacement is exactly what it sounds like: replacing an old motor with a new (and often more modern) motor. The first step involves inspecting the nameplate of your current motor along with any other related documentation provided by the manufacturer. This information–which contains data like dimensional parameters, the motor’s mechanical design, and electrical performance–is crucial as it provides suppliers with the whole picture and enables them to find the correct replacement that meets your application requirements. Afterwards, verify the compatibility of the new motor with your existing mounting configuration to ensure a swift electric motor installation.

2. Cost

In most cases, electric motor rewinds can cost around 40% to 75% of the price of a replacement. Rewinding generally costs more when there are other components that need to be addressed prior to the renewal of the windings. Should a repair plan incur more than 60% of a new motor, opting for a replacement instead is almost always the better option instead.

Beyond the initial investment required for a rewind or replacement, there is also the total overall running costs to consider. This can be calculated via total cost of ownership which considers several key variables such as the purchase cost, operational cost (i.e. the energy consumption over the motor’s service life), and annual repair and maintenance costs. In fact, the purchase price of a high duty cycle motor may account for only a small percentage of its total cost of ownership over a 10-year lifespan.

Older motors that are nearing the end of their expected lifespan tend to require more repairs, which is hardly the case for newer models. Overall, a rewind may have a lower purchase cost, but its total overall running costs may diminish any savings generated from the initial expense. The opposite occurs when getting a replacement as the higher efficiency and reliability means saving more on energy consumption and repairs in the long run.

3. Accessibility

Accessibility in this context refers to the availability of spare parts, specialised knowledge, and entire electric motor units that can replace your existing one. Rewinding motors that are outdated or made by uncommon brands generally entails longer waiting times for spare parts or having to search far and wide for someone with the expertise to do the repairs.

In worst case scenarios, these requirements are difficult or impossible to find in the first place. If a rewind is the only option, such as when using a motor whose special design makes it challenging to find a high-efficiency replacement, extensive custom repair work will be necessary. Similarly, it can also take some time for suppliers to find brand new replacement motors that perfectly match your old one’s characteristics.

4. Lead Times

Motor rewinding has shorter lead times on average compared to sourcing a new replacement motor. However, this can vary depending on parts availability and whether your motor needs to be shipped to a specialised rewinding facility.

While a motor replacement usually takes longer, they can often be quicker than rewinding if a supplier has the correct replacement ready in-stock and can be shipped immediately. Alternatively, those who cannot afford downtimes may have a backup or spare motors waiting on standby, further expediting the replacement process significantly.

5. Key Benefits

As mentioned previously, the main advantages of motor rewinding is the lower initial cost and faster average lead times. For those who are only concerned with the short-term expenses, this option is the best choice for resuming operations as quickly as possible. But while rewinding does restore the efficiency of old motors, the improvements gained will not surpass the unit’s original ratings.

On the other hand, getting a replacement motor lends to improved reliability and efficiency thanks to their higher-quality manufacturing and more complex designs. Moreover, there is the factory warranty to consider. Old motors are generally no longer under warranty coverage, while newer ones now enjoy better coverage with many extending beyond the typical 1-year period. This alone can significantly cut down repair costs. Last but not least, sourcing for parts for relatively newer motors is much less of a hassle than those that are several generations behind.

Conclusion

Deciding between motor rewinding and replacement hinges on various factors, including the extent of damage, cost-effectiveness, motor size, and operational efficiency. Motor rewinding can be a viable option for restoring functionality, particularly in cases of minor electrical faults or when the motor is costly to replace. However, it may result in slight efficiency losses, and frequent rewinding might not always be sustainable in the long run. On the other hand, replacing the motor ensures optimal performance with modern technology but comes at a higher upfront cost. Ultimately, assessing the motor’s condition, operational needs, and budget constraints will guide businesses in choosing the most suitable solution.